how does a brushless rc motor work

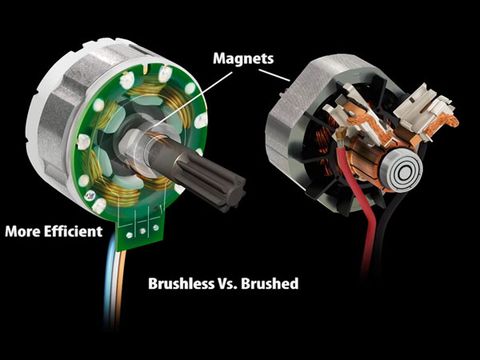

The magnets are attached to the motors bell and push and pull the motor as necessary. Electromagnets can also be used to generate power.

Brushless Vs Brushed Dc Motors When And Why To Choose One Over The Other Article Mps

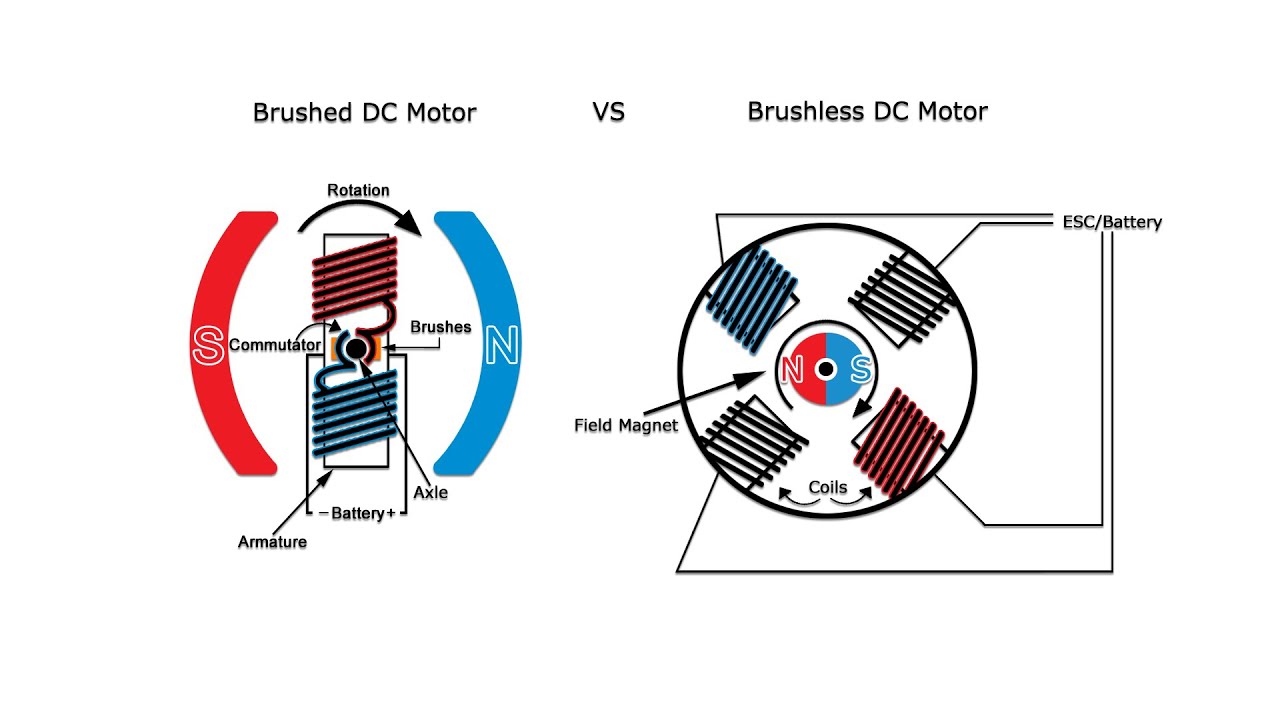

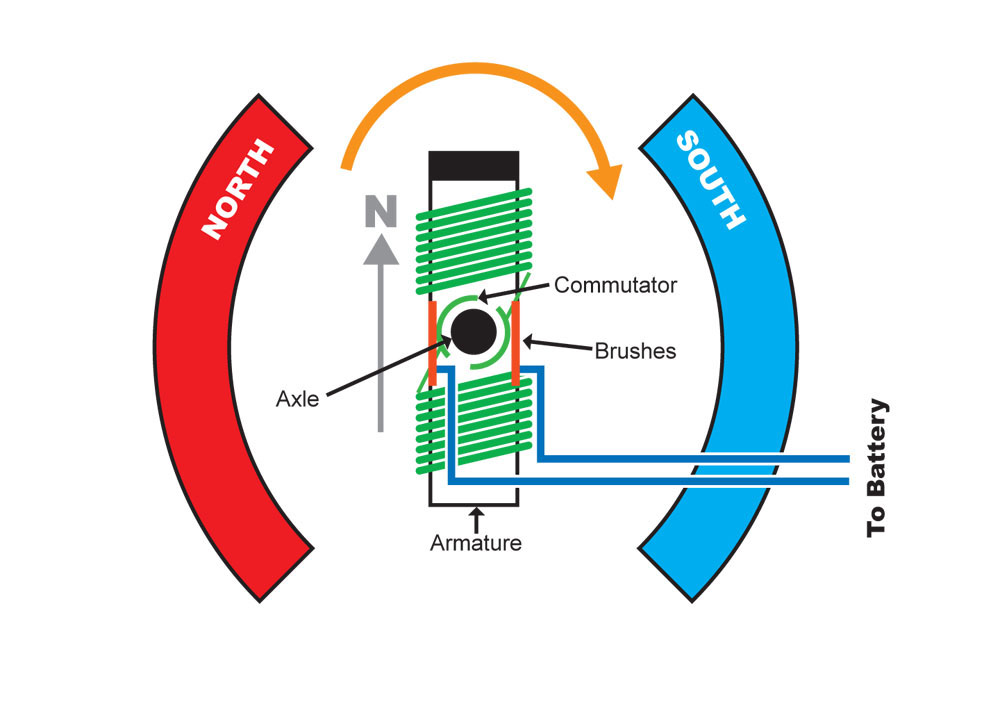

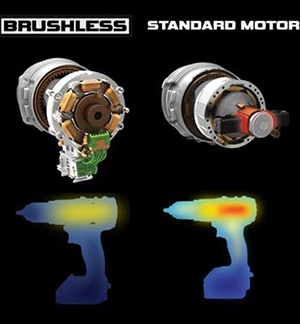

A brushed motor uses the brush to commutator contact to turn onoff a magnetic field at specific points of armature rotation.

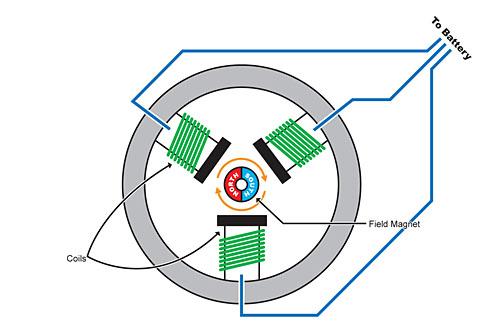

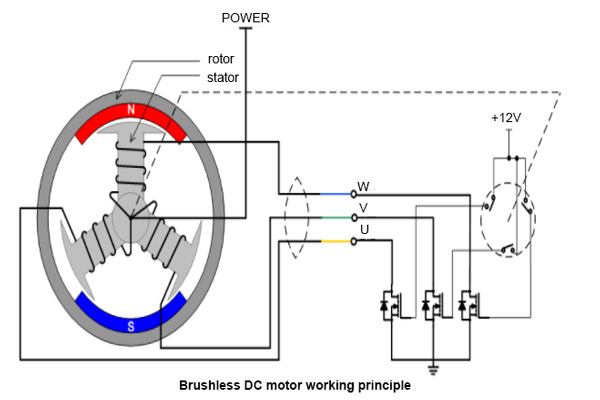

. Brushless 3-phase DC motors have 3 windings evenly spaced at 120-degree intervals around the periphery of the motor. The permanent magnets that would wrap around the armature in a normal motor are instead placed around the motor shaft and this assembly is called the rotor. Then you use a computer connected to high-power transistors to charge up the electromagnets as the shaft turns.

Like brushed DC motors brushless motors work by alternating the polarity of the windings on the interior of the motor. The rotor is the rotating component that holds the permanent magnets. The second and much less common method of timing adjustment is adjusting the physical endbell of the motor.

We break the numbers out as follows. The rotor consist of permanent magnets. The higher the torque the faster the RC car.

Sometimes this is just called a brushless control but in the RC world this is called an brushless ESC electronic speed control. The basic explanation of a brushless motors construction is that it is similar to a brushed motor except everything is inside out and there are no brushes at all. The formula to calculate Kv for brushless motors is.

It is determined by the number of winds on the armature and the strength of the magnets. In a brushless DC motor BLDC you put the permanent magnets on the rotor and you move the electromagnets to the stator. The more common and well known method of timing adjustment is done within the ESC.

There are two types of Brushless DC motors. Brushless motors however use electrical means of commutation. One end of each winding is connected in common and the other end is free to be driven externally.

How do you calculate the power of a brushless motor. A brushless motor is inside out compared to your GWS motor. 55 The second two.

A brushless DC motor is essentially flipped inside out eliminating the need for brushes to flip the electromagnetic field. In brushless DC motors the permanent magnets are on the rotor and the electromagnets are on the stator. In this example 50mm.

Take a look at the commutator on the GWS motor. 23s and multiply by 750 to convert the BHP to watts to determine the output power of the equivalent brushless electric motor. Brushless motors use a standard numbering scheme to describe their physical size and Kv rating.

The magnetic fields created when the coils are generated exert a pushpull force on the permanent magnets arranged around the outside of the casing. For brushless motors you would measure the RMS voltage between any two leads. The transistors swithc the field in a rotary fashion just like 3 phase power does in an industrial AC motor.

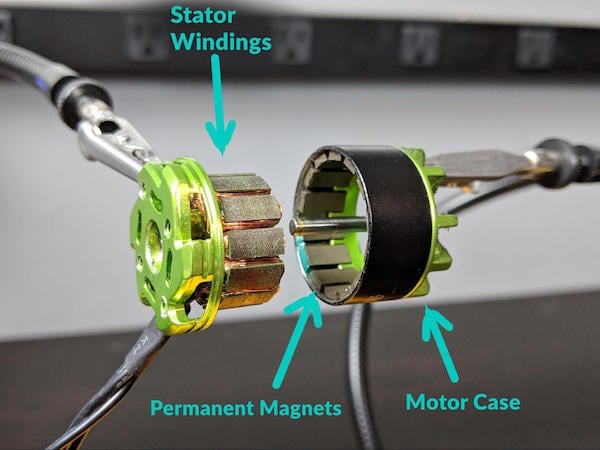

Motor you would use in the model. A brushless motor detects armature position electronically and turns onoff a magnetic field based upon armature position detection. Every brushless motor is made of two main parts a stator and a rotor.

There is no more heat resistance maintenance and therefore replacement. 50 55 - 3000 50 The first two numbers represent the diameter of the motors housing in millimeters. Lets assume we have a 5055-3000Kv Brushless Outrunner Motor.

The windings are glued to the inside of the can and the permanent magnets are bonded to the rotor. The increase in voltage does increase the total RPM output but this will not destroy a brushless motor. Inrunner and outrunner models.

Identify the maximum power BHP of the motor. There are 2 ways that you are able to alter the timing of a brushless motor. Help us to make future videos for you.

Divide this by 15 ie. Does a Motor Fail Electrically due to Current. A brushless DC motor is actually very similar to a generator such as one might find in a dynamo or turbine and so as it is driven round by the BLDC motor driver it will also start to generate electromagnetic force.

This is just speed divided by voltage but the 1414 term is to convert RMS voltage to peak voltage. Its cut into multiple sections. The torque of a brushless RC motor refers to how much rotational force can be applied to the vehicle.

A computer then charges the electromagnets in the stator to rotate the rotor a full 360-degrees. This design succeeds in eliminating motor brushes. The way a brushless motor works is by using electromagnets rather than brushes to spin the motor.

In the brushless the motor is inside-out with the field as the rotor and the windings as the stator. Make LEs efforts sustainable. An ESC or an Electronic Speed Controller controls the brushless motor movement or speed by activating the appropriate MOSFETs to create the rotating magnetic field so that the motor rotates.

Brushless Electric RC Cars Brushless In brushless motors the coils are located on the stator instead of the rotor. It is mechanically aligned to the magnet field. They require a control that decides when to switch the direction of current in the wires based on the relative position of the magnets and the wires.

Since the wires dont move you dont need brushes to transfer the electricity. Luckily for us the voltage in our RC domain do not come close to becoming an issue. The higher the frequency or the quicker the ESC goes through the 6 intervals the higher the speed of the motor will be.

Instead permanent magnets are placed on the rotor. The 095 term is fudge factor that has been found by hobbyists to give you the right answer. This essentially removes the requirement of brushes which makes this motor a lot more efficient.

Brushless Motor Brushless motors are the opposites of the brushed motors because in these the electromagnets stay stationary while magnets rotate. When rating a brushless RC motor it must have a high torque. The stator is static it does not move and it holds the electromagnets.

This then works against the forward voltage produced by the driver but crucially the frequency of the force is directly related to the speed of the rotor and can be. The current a brushless motor will see is directly related to the load. This method is more common with brushless motor for RC cars.

This system has all sorts of advantages.

Differences Between Brushed And Brushless Motors A Galcotv Tech Tip Youtube

The Brushed Dc Motor Still A Very Viable Option Part 1 Operation Electrical Engineering News And Products

Brushed Vs Brushless Motors A Beginner S Guide Techno Faq

Brushed Motors Vs Brushless Motors For Quadcopter Oscar Liang

What Is A Brushless Motor And How Does It Work

What Is A Brushless Motor And How Does It Work

How Brushless Motor And Esc Work Futurelab3d

The Difference Between Brushed And Brushless Motors

How Brushless Motor And Esc Work Futurelab3d

How Brushless Motor And Esc Work Futurelab3d

Brushless Vs Brushed Motor Why You Should Know The Difference Cdz

What Is A Brushless Motor And How It Works Torque Hall Effect 3d Animation Youtube

Brushless Vs Brushed Motor What S The Difference

How A Brushless Dc Motor Works Custom Maker Pro

Brushless Vs Brushed Motor What S The Difference

Brushless Vs Brushed Dc Motors When And Why To Choose One Over The Other Article Mps

Brushless Dc Motor How It Works Ato Com

Motor Control Solutions Brushless Dc Vs Pmsm Motor Controller